Subfloor options

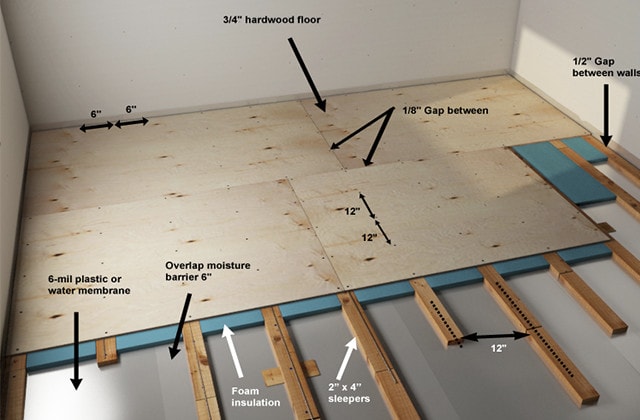

Some garage flooring options are designed to be installed directly on a concrete surface. Others require some type of subfloor to protect them from the effects of cold, damp concrete. Check the flooring manufacturer’s installation instructions before you make your choice.

Go to the article: “Is a subfloor necessary in the basement?” It will help you choose the correct subfloor for your needs. Follow our helpful tips below before installing engineered floor panels in your basement:

Before you begin

- Check your local building code, and pay special attention to rules concerning vapor barriers, span ratings (subfloor thickness) and floor drains.

- Use a digital moisture detector to measure the moisture content (MC) of the concrete slab.

- Read the flooring manufacturer's guidelines for the product you plan to install, and pay particular attention to requirements as regards the structure and moisture content of the concrete slab.

- Manufacturers may require sub-floor and flooring materials to be acclimated prior to installation (generally 24-72 hours).

- Wear eye protection and work gloves, and use an approved dust mask or respirator when cutting pressure-treated wood.