Models of screws

Models

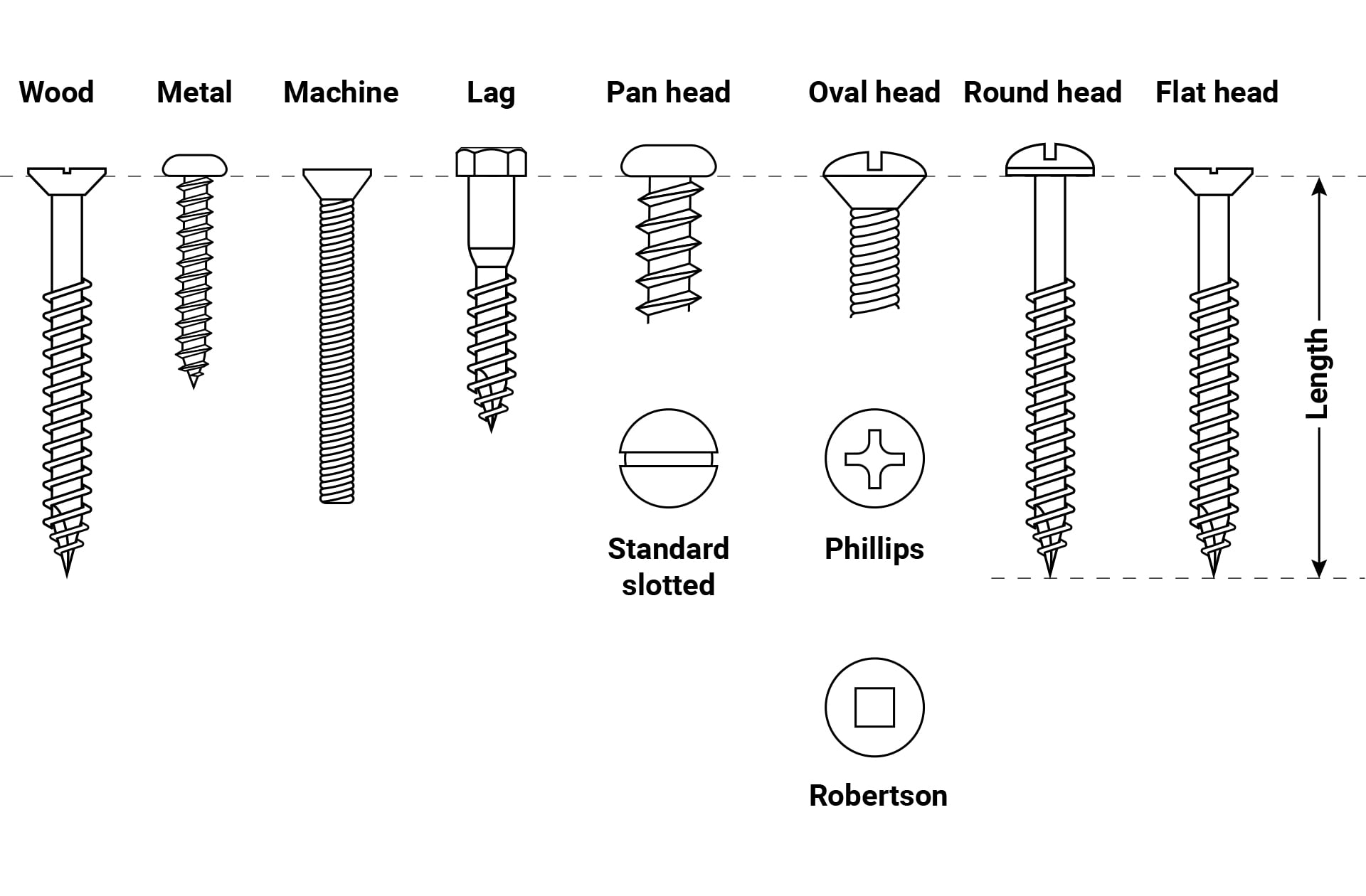

The right screw can speed up and simplify a job, and provide the lasting hold and appearance you expect. Here are the general types and features of screws offered in the hardware aisle.

Soft-steel wood screws

- Traditional wood screw.

- Single-helix thread and flat head.

- Length: 3/8" to 6".

- Gauge: 2 to 18.

Hardened-steel wood screws

- Suitable for all types of wood.

- Double-helix thread and high-strength steel allows it to be driven without a pilot hole.

- Length: 3/8" to 4".

- Gauge: 3 to 12.

Wood screws for decks

- Hardened-steel screw specifically designed to resist corrosion.

- Drives quickly.

- Length: 1" to 4".

- Gauge: 8 to 10.

Particle board screws

- Wood screws

- Large, deep, sharp threads cut through particle board glue and prevent the screw from being torn out.

Lag screws

- Thick screw with a hexagonal or square head that you drive with a wrench or socket set.

- Use it instead of a bolt when the location of the nut would be inaccessible.

Self-tapping Screws

- Versatile, hardened-steel screw

- The sharp threads can cut into metal, plastic, fibreglass, or other materials without pre-drilling.

- Shank is threaded to the head.

- Choose a size that is slightly longer than the combined thickness of the pieces.

- Length: ¼" to 2 ½".

- Gauge: 4 to 14.

Machine screws

- Used for the assembly of metal parts or to attach hardware.

- Usually driven into a threaded or pre-drilled hole

Drywall screws

- Thin, tempered, and threaded from tip to head so it screws into the drywall

- Can have coarse, widely-set threads for screwing into wood studs or finer, medium-set threads for screwing into metal.

- Length: 1" to 3".

Concrete and masonry screws

- Hardened-steel screws

- The double threading is made for fastening wood or metal to concrete, brick, or mortar joints without an anchor.